Researchers develop rechargeable hybrid-seawater fuel cell; highly energy density, stable cycling

Green Car Congress

NOVEMBER 24, 2014

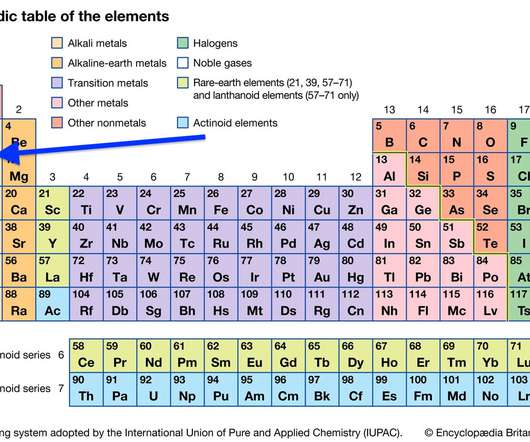

The circulating seawater in the open-cathode system results in a continuous supply of sodium ions, endowing the system with superior cycling stability that allows the application of various alternative anodes to sodium metal by compensating for irreversible charge losses. an alloying material), in full sodium-ion configuration.

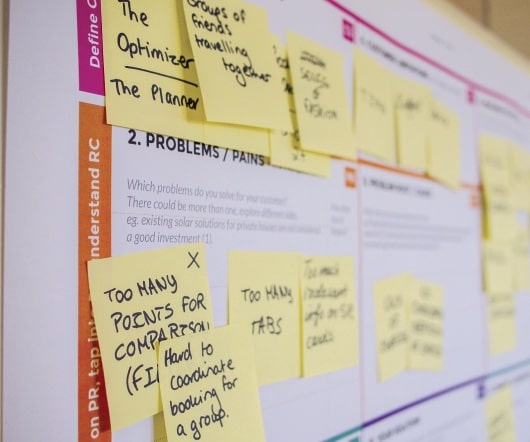

Let's personalize your content