Ultium Cells and Li-Cycle collaborate to expand recycling in North America

Green Car Congress

MAY 12, 2021

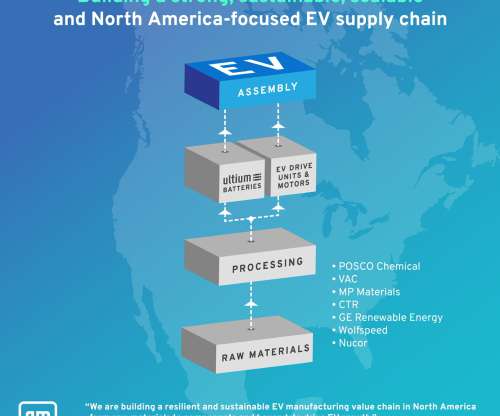

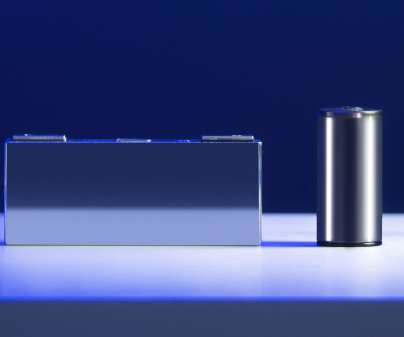

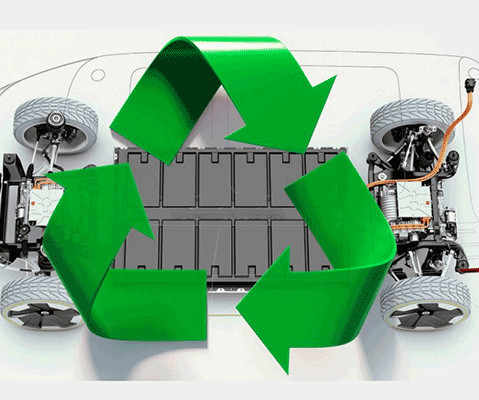

Ultium Cells LLC, a joint venture between General Motors and LG Energy Solution, announced an agreement with Li-Cycle to recycle up to 100% of the material scrap from battery cell manufacturing. Ninety-five percent of these materials can be used in the production of new batteries or for adjacent industries. Ultium cells in module.

Let's personalize your content