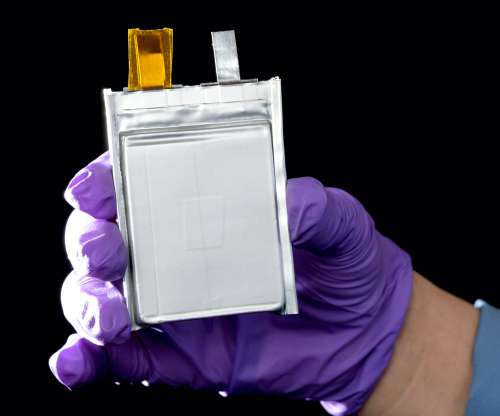

GM boosting face mask production; sharing mask manufacturing plans

Green Car Congress

APRIL 10, 2020

Based on the number of requests for face masks for frontline workers, GM is increasing its production capacity for face masks at its Warren, Michigan facility. And we recognize it would be counterproductive for GM—or any other manufacturer—to compete for supplies with existing medical mask companies.

Let's personalize your content