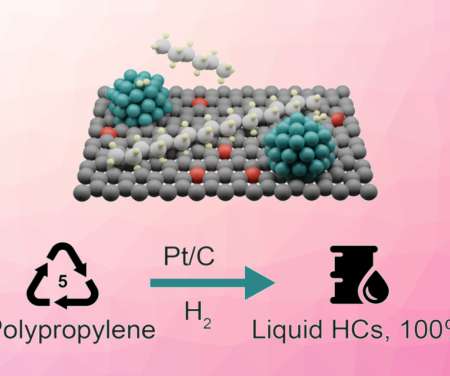

U Delaware team develops chemocatalytic process to convert waste polypropylene to lube oils

Green Car Congress

AUGUST 27, 2021

They were able to convert amorphous polypropylene and everyday bags and bottles effectively to lubricants with yields up to 80+%. The reaction network involves the sequential conversion of polymer into the oil with a gradual decrease of molecular weight until ?700–800 A paper on their work is published in the journal ACS Catalysis.

Let's personalize your content