New liquid alloy electrode significantly lowers operating temperature of sodium-beta batteries; improved performance

Green Car Congress

AUGUST 1, 2014

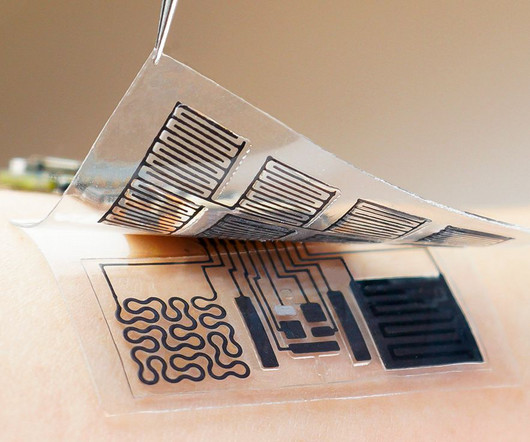

Researchers at Pacific Northwest National Laboratory (PNNL) have devised an alloying strategy that enables sodium-beta batteries to operate at significantly lower temperatures. The new electrode enables sodium-beta batteries to last longer, helps streamline their manufacturing process and reduces the risk of accidental fire.

Let's personalize your content