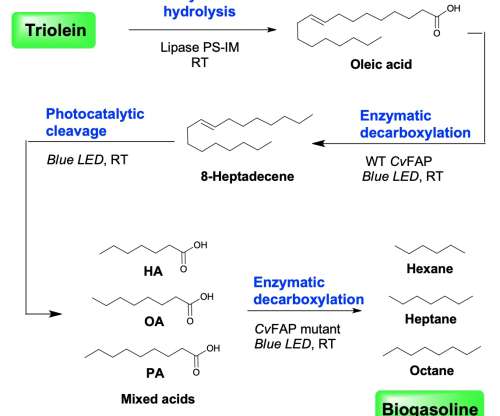

Zhejiang team develops photo-chemo-biocatalytic pathway to convert triolein to biogasoline

Green Car Congress

AUGUST 11, 2022

Researchers from Zhejiang University in China have developed a photo-chemo-enzymatic multi-step combination pathway for the highly efficient and environmentally friendly preparation of biogasoline from cheap and sustainable triolein using solar energy and atmospheric O 2 under mild conditions. —Xu et al. doi: 10.1039/D2GC01992B.

Let's personalize your content