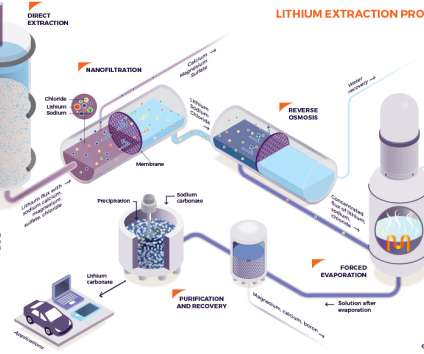

Rio Tinto commits $2.4B for Jadar lithium project; planning 58,000 tons/year lithium carbonate by 2029

Green Car Congress

JULY 28, 2021

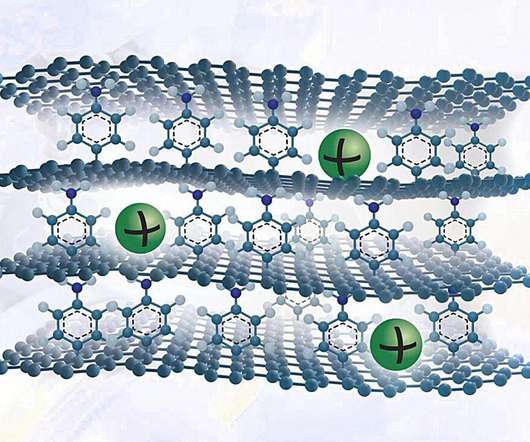

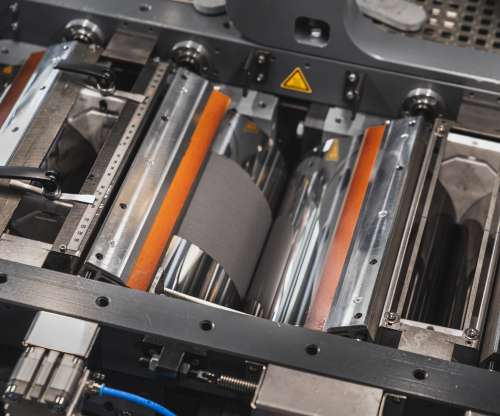

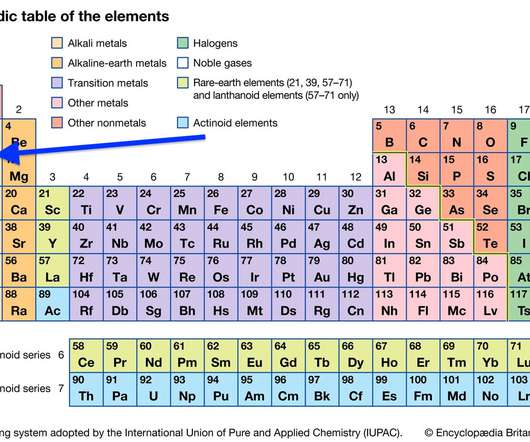

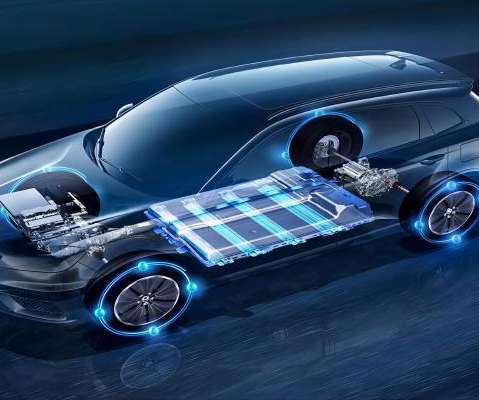

The Jadar project would support the evolution of Rio Tinto—one of the world’s largest miners—into a chemical producer to make battery-grade lithium carbonate, a critical mineral used in large-scale batteries for electric vehicles and storing renewable energy. This is a significant moment for the lithium industry.

Let's personalize your content