NIMS researchers report 500 Wh/kg+ Li-air battery

Green Car Congress

JANUARY 24, 2022

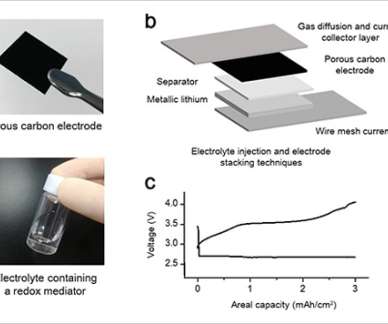

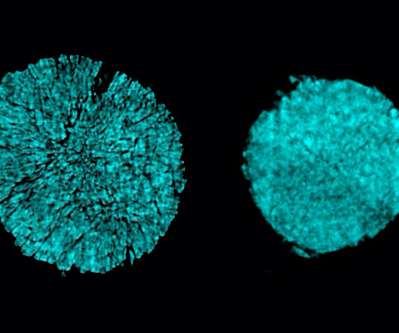

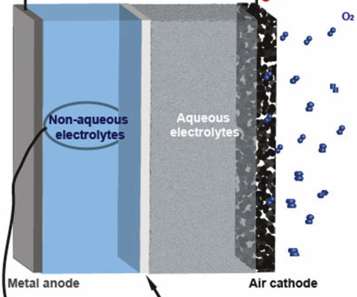

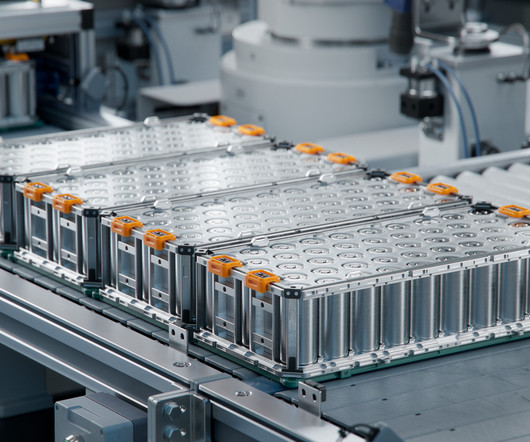

Researchers at Japan’s National Institute for Materials Science (NIMS) and the NIMS-SoftBank Advanced Technologies Development Center have developed a lithium-air battery with an energy density of more than 500 Wh/kg—significantly higher than currently lithium ion batteries.

Let's personalize your content