Lithium Sulfur, Lithium Carbon — Batteries Have Come A Long Way, Baby

CleanTechnica EVs

SEPTEMBER 23, 2021

Lithium sulfur and lithium carbon batteries are almost ready for prime time.

This site uses cookies to improve your experience. By viewing our content, you are accepting the use of cookies. To help us insure we adhere to various privacy regulations, please select your country/region of residence. If you do not select a country we will assume you are from the United States. View our privacy policy and terms of use.

CleanTechnica EVs

SEPTEMBER 23, 2021

Lithium sulfur and lithium carbon batteries are almost ready for prime time.

Green Car Congress

APRIL 3, 2018

Lignosulfonate, a sulfonated carbon waste material, is a major by-product in the papermaking industry. Researchers at Rensselaer Polytechnic Institute (RPI) have now developed a method to use this cheap and abundant waste byproduct to build a components for lithium-sulfur batteries. per cycle over 200 cycles. Click to enlarge.

Green Car Congress

JUNE 15, 2023

developer of the Lyten 3D Graphene decarbonization supermaterials platform, commissioned its Lithium-Sulfur battery pilot line at its facility in Silicon Valley. The pilot line will deliver cells that exceed conventional Nickel-Cobalt-Manganese (NMC) lithium-ion battery gravimetric energy densities. Lyten, Inc.,

Green Car Congress

MARCH 28, 2022

Lithium-sulfur batteries are prospects for future batteries as they are made from cheaper and more environmentally friendly materials than lithium-ion batteries. They also have higher energy storage capacity and work well at much lower temperatures. However, they suffer from short lifetimes and energy loss.

Green Car Congress

JUNE 1, 2015

Stanford University scientists have created a new ultrahigh surface area three-dimensional porous graphitic carbon material that significantly boosts the performance of energy-storage technologies. The maximum surface area achieved with conventional activated carbon is about 3,000 m 2 g –1.

Green Car Congress

FEBRUARY 24, 2021

Scientists from Gwangju Institute of Science and Technology (GIST), Korea, have found that a new catalyst material can improve lithium–sulfur battery life significantly. In this approach, a carbon layer is placed directly on the conventional sulfur cathode. times the level of conventional lithium-sulfur batteries.

Green Car Congress

DECEMBER 21, 2018

Researchers at Jiangsu Normal University in China have devised a boron-doped carbon-sulfur (BCS) aerogel with consecutive “core-shell” stuctures as a binder-free cathode for lithium-sulfur batteries. Good porous structures of BCS aerogel can provide sufficient space for the expansion of active sulfur.

Green Car Congress

APRIL 17, 2023

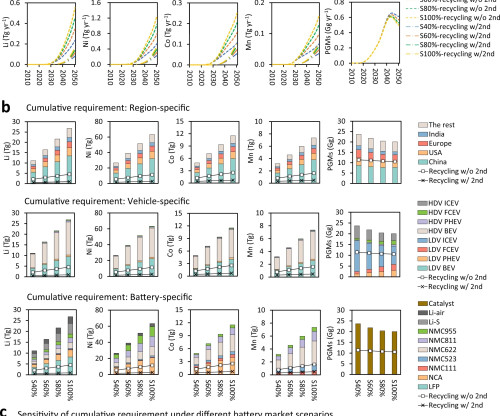

Recycling w/o 2nd” indicates retired batteries that are directly recycled without a second life as energy storage systems (ESSs). Decarbonization targets for road transportation should be coupled with electric vehicle deployment, the timing of carbon peak and neutrality, and accurate emission budgets. Zhang et al.

Green Car Congress

SEPTEMBER 30, 2019

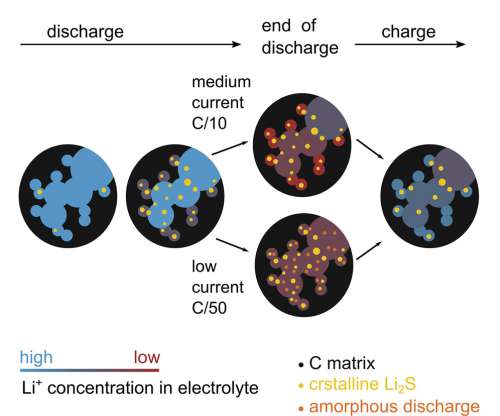

To develop higher capacity batteries, researchers have looked to lithium-sulfur batteries because of sulfur’s high theoretical capacity and energy density. It also consumes fresh lithium and electrolytes, and reduces battery performance.

Green Car Congress

MAY 20, 2019

Researchers at Beihang University in Beijing have developed a linear molecule sulfur-rich organic material as sulfur cathode for a lithium-sulfur battery. The tetramethylthiuram disulfide-sulfur (TMTD-S) cathode material delivers an initial capacity of 685?mAh 1 at 0.2C (1?C?=?1061?mAh 1 after 200 cycles.

Baua Electric

APRIL 12, 2024

Given India’s dependence on 100% imported lithium-ion cells for electric vehicle batteries, there exists a compelling drive to cultivate indigenous cell and battery manufacturing capacities to meet the burgeoning demands. We think Zeta Energy’s world-class capabilities in lithium-sulfur battery technology will help us get there faster.”

Green Car Congress

MAY 16, 2014

Researchers at Tsinghua University have combined two types of carbon materials to create a new composite sulfur cathode material for a high-energy and high-power lithium-sulfur battery. Carbon atoms have six electrons: two are in 1s states, and four are valence electrons, occupying the 2s and 2p orbitals.

Green Car Congress

DECEMBER 16, 2014

Vasant Kumar at the University of Cambridge and Professor Renjie Chen at the Beijing Institute of Technology has devised a three-dimensional hierarchical sandwich-type graphene sheet-sulfur/carbon (GS-S/C ZIF8-D ) composite to address performance-related issues in Lithium-sulfur batteries such as low efficiency and capacity degradation.

Green Car Congress

SEPTEMBER 30, 2014

Fraunhofer IWS in Dresden, Germany will hold its 3rd annual workshop on Lithium-sulfur batteries from 12-13 November 2014. As with the prior Lithium-Sulfur Battery Workshops in 2012 and 2013, this year’s symposium will bring together an international audience of scientists and industrial customers.

Green Car Congress

AUGUST 26, 2014

The composite shows good rate performance and excellent cycling stability for use as a cathode material in Lithium-sulfur batteries. Another approach is to protect the anode to reduce the sulfur shuttle effect, and thereby extend cycling life.

Green Car Congress

JANUARY 19, 2018

A team of researchers led by scientists at the US Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) have designed an active polyelectrolyte binder (PEB) that actively regulates key ion transport processes within a lithium-sulfur battery, and have also shown how it functions on a molecular level.

Green Car Congress

APRIL 23, 2018

The “classic” high-energy capacity Lithium-sulfur battery is predicated on the use of a sulfur-based cathode and a Lithium-metal anode. Among the issues hampering the commercialization of this attractive technology are the safety and performance issues associated with the use of the lithium-metal anode.

Green Car Congress

MAY 16, 2016

Researchers from Hunan University and Changsha University in China have designed 3D hierarchical porous nitrogen-doped aligned carbon nanotubes (HPNACNTs) with well-directed 1D conductive electron paths as scaffold to load sulfur for use as a high-performance cathode in Li-S batteries. —Deng et al.

Green Car Congress

FEBRUARY 10, 2015

A team from the China University of Geosciences has taken a novel approach to stabilizing Lithium-sulfur batteries by functionalizing the carbon-sulfur cathode with DNA. Rechargeable lithium/sulfur battery promises an appealing candidate for energy storage to power portable devices and electric vehicles.

Green Car Congress

MARCH 31, 2016

Lithium-sulfur batteries—comprising a sulfur cathode and Li metal anode—are widely seen as a very promising next-generation electric energy storage system due to their very high theoretical specific energy (2550 Wh kg −1 ) and energy density (2862 Wh L −1 ). Background. Bhattacharya, P.,

Green Car Congress

FEBRUARY 19, 2014

The high stability of these electrolytes enables batteries that can work at very high temperatures, high voltages and with next-generation “beyond lithium-ion” technologies like lithium-sulfur and metal-air batteries. Boulder Ionics Corp., —CSIRO Research Scientist Dr. Adam Best.

Green Car Congress

APRIL 30, 2010

The US Department of Energy is awarding $106 million in funding for 37 research projects selected in the second round by the DOE’s Advanced Research Projects Agency-Energy (ARPA-E). Novel Biological Conversion of Hydrogen and Carbon Dioxide Directly into Biodiesel. Earlier post.). Earlier post.) Engineering E. per gallon.

Green Car Congress

JANUARY 9, 2013

Researchers at Stanford University and SLAC led by Stanford associate professor Yi Cui have used a sulfur–TiO 2 yolk–shell design for a cathode material for a lithium-sulfur battery that achieved an initial specific capacity of 1,030?mAh?g This is the highest performing sulfur cathode in the world, as far as we know.

Baua Electric

JANUARY 12, 2024

Sodium-ion technology holds the promise of a more cost-effective energy storage compared with today’s widely used lithium-ion battery technology, the company said. To achieve these sales targets, Stellantis is securing approximately 400 GWh of battery capacity. and sodium-ion with Tiamat.

Green Car Congress

NOVEMBER 28, 2012

of additive manufacturing more widely for energy systems. ARPA-E OPEN 2012 selections: Carbon Capture. Energy-Efficient Electrochemical Capture and Release of CO 2. Arizona State University (ASU) will develop an innovative electrochemical technology for the capture of carbon dioxide coming. liquid carbon dioxide.

Green Car Congress

NOVEMBER 1, 2012

Electrochemical properties of sulfur-carbon composite. (a) Researchers in China are proposing a new strategy for addressing some of the issues limiting the commercialization of high energy density lithium-sulfur batteries ( earlier post ): using small sulfur allotropes (different forms of the same element)—i.e.,

Baua Electric

JANUARY 12, 2024

Sodium-ion technology holds the promise of a more cost-effective energy storage compared with today’s widely used lithium-ion battery technology. Stellantis is on track to become a carbon net zero corporation by 2038, all scopes included, with single-digit percentage compensation of remaining emissions.

Green Car Congress

AUGUST 22, 2013

The US Department of Energy (DOE) Advanced Research Projects Agency - Energy (ARPA-E) will award approximately $36 million to 22 projects to develop transformational electric vehicle (EV) energy storage systems using innovative chemistries, architectures and designs. National Renewable Energy Laboratory.

Green Car Congress

MAY 2, 2017

Li-sulfur batteries are looked to as a likely next-generation higher energy density energy storage system due to the high theoretical capacity, low cost and high earth abundance of sulfur. A paper on their work is published in the ACS journal Nano Letters. Credit: ACS, Chen et al. Junzheng Chen, Wesley A.

Green Car Congress

JULY 12, 2017

One of the most significant impediments to an increased market share for plug-in vehicles is the high cost of rechargeable energy storage. The new cell and BMS are intended to achieve 400Wh/kg cell energy density with practical cycle life and performance metrics. This project was led by OXIS and part-funded by Innovate UK.

Green Car Congress

JANUARY 1, 2015

A team at the Suzhou Institute of Nano-Tech and Nano-Bionics (SINANO) has demonstrated that the electrochemical performance of sulfur nanoparticles (NPs) in the cathode of a Lithium-sulfur battery is critically dependent on the sulfur particle size. When paired with lithium metal anode to form rechargeable lithium?sulfur

Green Car Congress

JULY 10, 2015

As one of the most intensely investigated technologies in the electrochemical energy storage field, lithium−sulfur (Li−S) batteries have observed rapid improvements in their properties in recent years. A paper explaining their work appears in the ACS journal Nano Letters. —Chen et al. 5b01837.

Green Car Congress

JANUARY 7, 2015

A team from the University of Rome Sapienza has developed a rechargeable lithium-ion polymer battery based on the combination of a high capacity sulfur-carbon cathode, nanostructured Li x Sn-C anode and polysulfide-added PEO-based gel membrane. Moreover, the addition of a dissolved polysulfide (i.e.

Green Car Congress

OCTOBER 26, 2015

This will be followed by an assessment of the perceived technological barriers and the potential energy density gains for so-called post-LiBs, namely lithium-oxygen and lithium-sulfur batteries. On the Li-sulfur side, it is difficult to achieve the expected gravimetric energy density from a lithium sulfur battery-system.

Green Car Congress

DECEMBER 31, 2012

Researchers at Cornell University are proposing a new scheme for cathodes for lithium-sulfide batteries ( earlier post ) to prevent lithium polysulfide dissolution and shuttling during electrochemical cycling. polyacrylonitrile), to control the distribution of lithium sulfide in the host material. Earlier post.) Earlier post.)

Green Car Congress

FEBRUARY 9, 2015

Lithium sulfur (Li?S) S) battery is a promising candidate for next- generation energy storage devices. However, lithium metal has safety and cyclability issues due to the formation of lithium dendrites; the pulverized and detached lithium metal formed during cycling can result in explosions when exposed to air.

Green Car Congress

APRIL 28, 2016

Lithium-sulfur (Li-S) batteries are of great interest as next-generation energy storage solutions, especially for electric vehicles, due to their high energy density, low production cost and environmental friendliness.

Green Car Congress

DECEMBER 4, 2013

carbon composite as cathodes in ether-based electrolyte. New composite materials based on selenium (Se) sulfides used as the cathode in a rechargeable lithium-ion battery could increase Li-ion density five times, according to research carried out at the US Department of Energy’s Advanced Photon Source at Argonne National Laboratory.

Green Car Congress

APRIL 11, 2015

S batteries, one effective strategy is to confine sulfur and polysulfides into carbonaceous matrix and meanwhile improve the electrical conductivity of overall electrodes. carbon hybrids and demonstrated the improved electrochemical performances. Batteries Graphene Li-Sulfur' —Li et al.

Green Car Congress

JULY 8, 2013

They suggest that a low cost, non-flammable and heavy-metal-free aqueous cathode can contribute to the feasibility of scale-up of lithium-iodine batteries for practical energy storage. Li metal with 1 M of LiPF 6 in ethylene carbonate (EC)/dimethyl carbonate (DMC) electrolyte was used for the anode.

Green Car Congress

AUGUST 11, 2016

Lithium-sulfur batteries are extremely attractive as a next-generation energy storage solution due to their high theoretical energy density (2600 W·h·kg −1 ), environmental friendliness, and low cost due to the earth-abundant resource of elemental sulfur—also a byproduct from the petroleum industry.

Green Car Congress

MAY 28, 2015

Advanced Lithium Sulfur Battery for Electric Vehicle Applications Successful completion of the current program will make significant contribution toward development of the key energy storage system that can be used in the long range EVs to improve the vehicles energy efficiency and running range. 150,000.00.

Green Car Congress

FEBRUARY 11, 2012

The introduction of hydrogen into the engine virtually eliminates fuel emissions while greatly reducing the emissions of hydrocarbons and carbon monoxide. In 2007, Vorbeck signed a worldwide license agreement with Princeton University for a patented method from the the Aksay Labs for manufacturing graphene at commercial scale.

Green Car Congress

AUGUST 10, 2011

This project will develop a novel low cost route to carbon fiber using a lignin/PAN hybrid precursor and carbon fiber conversion technologies leading to high performance, low-cost carbon fiber. Increased availability of low cost carbon fiber can enable vehicle weight reduction and improvement in fuel economy.

Expert insights. Personalized for you.

We have resent the email to

Are you sure you want to cancel your subscriptions?

Let's personalize your content