First prototype carbon fiber chassis delivered from new £50M McLaren Automotive innovation and manufacturing center

Green Car Congress

MARCH 25, 2019

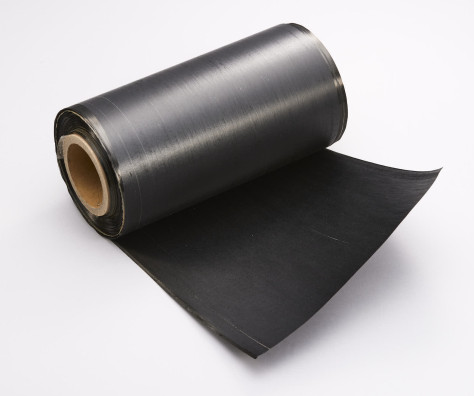

The first prototype carbon fiber MonoCell, the tub that forms the main structure of McLaren’s cars, has been shipped from the company’s new £50-million (US$66-million) innovation and production center in Yorkshire to the McLaren Production center (MPC) in Woking, Surrey. All McLaren’s sportscars and supercars will be hybrid by 2024.

Let's personalize your content