Lithium Sulfur, Lithium Carbon — Batteries Have Come A Long Way, Baby

CleanTechnica EVs

SEPTEMBER 23, 2021

Lithium sulfur and lithium carbon batteries are almost ready for prime time.

This site uses cookies to improve your experience. By viewing our content, you are accepting the use of cookies. To help us insure we adhere to various privacy regulations, please select your country/region of residence. If you do not select a country we will assume you are from the United States. View our privacy policy and terms of use.

CleanTechnica EVs

SEPTEMBER 23, 2021

Lithium sulfur and lithium carbon batteries are almost ready for prime time.

Green Car Congress

MAY 26, 2023

Stellantis Ventures, the corporate venture fund of Stellantis, has invested in materials innovation and applications company Lyten to accelerate the commercialization of Lyten 3D Graphene applications for the mobility industry, including the LytCell Lithium-Sulfur EV battery ( earlier post ), lightweighting composites, and novel on-board sensing.

Green Car Congress

JUNE 15, 2023

developer of the Lyten 3D Graphene decarbonization supermaterials platform, commissioned its Lithium-Sulfur battery pilot line at its facility in Silicon Valley. Battery delivery will be used to support testing, qualification and initial commercialization across the sectors. Lyten, Inc., Earlier post.)

Green Car Congress

MARCH 26, 2019

The relationship between cathode porosity and predicted cathode-specific volumetric energy density e v (a) and gravimetric energy density e g (b) of the hybrid Mo 6 S 8 /S 8 cathode with all carbon included (HMSC) and C/S 8 cathode with different C/S 8 and Mo 6 S 8 /S 8 ratios. The net effect of using the new material is substantial.

Green Car Reports

MAY 25, 2023

Volvo’s upcoming EX30 is going for the brand’s smallest-ever carbon footprint. Stellantis sees lithium-sulfur battery tech in its future. And the BMW i5 looks much like a gasoline 5-Series. Is that a good thing? This and more, here at Green Car Reports.

Green Car Congress

APRIL 3, 2018

Lignosulfonate, a sulfonated carbon waste material, is a major by-product in the papermaking industry. Researchers at Rensselaer Polytechnic Institute (RPI) have now developed a method to use this cheap and abundant waste byproduct to build a components for lithium-sulfur batteries. per cycle over 200 cycles.

Green Car Congress

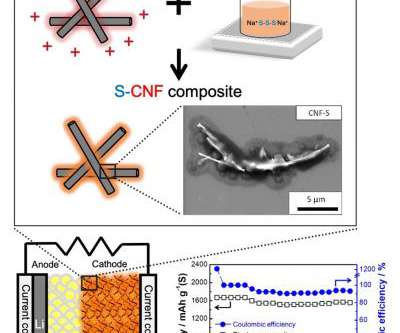

APRIL 13, 2020

Researchers at Toyohashi University of Technology in Japan have developed an active sulfur material and carbon nanofiber (S-CNF) composite material for all-solid-state Li-sulfur batteries using a low-cost and straightforward liquid phase process. Copyright Toyohashi University Of Technology. —Phuc et al.

Green Car Congress

MAY 22, 2017

Researchers at the Helmholtz-Zentrum Berlin für Materialien und Energie (HZB), with colleagues from Humboldt-Universität zu Berlin and University of Potsdam, have fabricated a nanomaterial made from nanoparticles of a titanium oxide compound (Ti 4 O 7 ) for use as a cathode material in lithium-sulfur batteries. Credit: HZB.

Baua Electric

MAY 10, 2024

Photo: Lyten In a milestone, supermaterials trailblazer Lyten has shipped lithium-sulfur (Li-S) batteries to Stellantis and other US and EU OEMs for testing. Ah Li-S pouch cells is the first major step in the commercial evaluation of lithium-sulfur batteries by leading US and European automakers.

Green Car Congress

APRIL 19, 2020

Jian Liu and Prof.Zhongshuai Wu from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences have developed Fe 1-x S-decorated mesoporous carbon spheres as a cathode material for lithium-sulfur batteries. This further causes low capacity and stability of lithium-sulfur batteries.

Baua Electric

JUNE 3, 2024

US-based chemical manufacturer Lyten has started shipping lithium-sulfur A sample cells to its investor Stellantis and other US and EU automotive OEMs for evaluation. The battery samples are being manufactured on Lyten’s semi-automated pilot line in San Jose, California, which opened in May 2023.

Green Car Congress

FEBRUARY 14, 2022

-sulfur phase within carbon nanofibers that enables successful operation of Lithium-Sulfur (Li-S) batteries in carbonate electrolyte for 4000 cycles. Carbonates are known to adversely react with the intermediate polysulfides and shut down Li-S batteries in first discharge. —Pai et al.

Green Car Congress

JUNE 7, 2020

Scientists from the Daegu Gyeongbuk Institute of Science and Technology, Korea, have developed a novel silica-based cathode for lithium–sulfur batteries, thereby enabling the realization of batteries that can last for more than 2,000 charge/discharge cycles. However, using sulfur in batteries is tricky for two reasons.

Green Car Congress

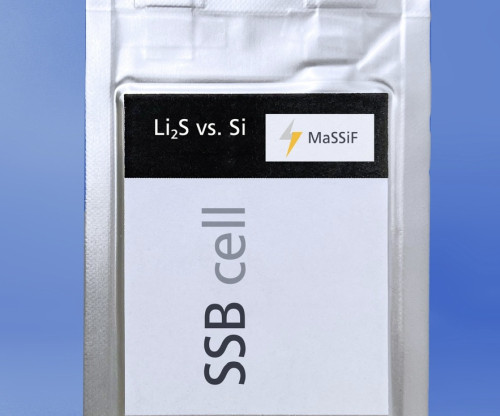

APRIL 26, 2023

The Fraunhofer Institute for Material and Beam Technology IWS in Dresden is leading a research project targeting a new generation of sulfur-based batteries. The combination with sulfur as the cathode active material holds particular promise. However, the anode poses major challenges in the battery's processing and operation.

Green Car Congress

FEBRUARY 15, 2013

Electrochemical performance of the modified hollow carbon nanofiber cathode. (a) a) Specific capacities of the PVP modified sulfur cathode at C/5, C/2 and 1C cycling rates. (b) Lithium sulfur batteries are of great interest due to their high specific energy and relatively low cost (e.g., Credit: ACS, Zheng et al.

Green Car Congress

JUNE 3, 2012

Researchers from Hanyang University in Korea and the University of Rome Sapienza (Italy) have developed a lithium-sulfur battery employing a high-performance mesoporous hard carbon spherules-sulfur cathode and a stable, highly conducting electrolyte. 2012), An Advanced Lithium-Sulfur Battery.

Green Car Congress

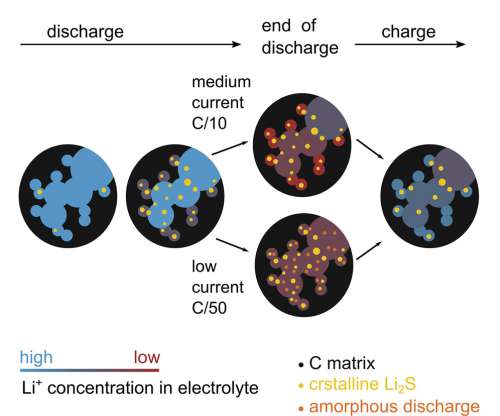

MARCH 28, 2022

Lithium-sulfur batteries are prospects for future batteries as they are made from cheaper and more environmentally friendly materials than lithium-ion batteries. Results indicate that precipitates grow mostly in number, not in size, and that the structure of the carbon matrix is not affected.

Green Car Congress

SEPTEMBER 7, 2013

Kentucky Governor Steve Beshear announced that start-up lithium-sulfur battery company NOHMs (Nano Organic Hybrid Materials) Technologies Inc. has selected to locate its research, manufacturing and product development facility for military, cell phone and electric vehicle lithium-ion batteries in Lexington.

Green Car Congress

MARCH 30, 2022

Berlin-based Theion , a developer of lithium-sulfur cathode technology, appointed Dr. Ulrich Ehmes as CEO and announced the upcoming commercial availability of its Crystal Battery for applications, beginning with the aerospace sector. A proprietary solid-state polymer electrolyte operates in the voids of the sulfur wafer.

Green Car Congress

JULY 31, 2012

Researchers at Oak Ridge National Laboratory have developed a high-performance lithium-sulfur battery using. nitrogen-doped mesoporous carbon (NC) and sulfur to prepare a composite cathode and an ionic-liquid electrolyte of 0.5?m Their study is published in the journal ChemSusChem. —Sun et al. and Dai, S.

Green Car Congress

FEBRUARY 24, 2021

Scientists from Gwangju Institute of Science and Technology (GIST), Korea, have found that a new catalyst material can improve lithium–sulfur battery life significantly. To improve battery life, scientists have been looking for catalysts that can make this degradation efficiently reversible during use. Capacity Lithium?Sulfur

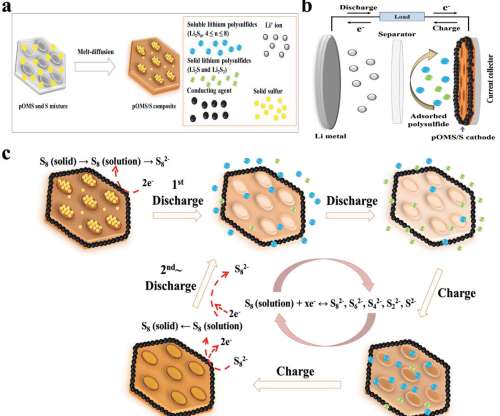

Green Car Congress

NOVEMBER 26, 2018

Researchers from Western University, Canadian Light Source, and the Chinese Academy of Sciences have proposed a novel solid-phase Li-S transformation mechanism that enables high energy Li-S batteries in conventional Li-ion carbonate electrolytes. Schematic of a lithium sulfur battery in carbonate-based electrolyte.

Green Car Congress

DECEMBER 21, 2018

Researchers at Jiangsu Normal University in China have devised a boron-doped carbon-sulfur (BCS) aerogel with consecutive “core-shell” stuctures as a binder-free cathode for lithium-sulfur batteries. These problems result in low specific capacity and poor cycling life of Li-S batteries.

Green Car Congress

NOVEMBER 5, 2018

Lithium-sulfur (Li-S) batteries, despite their high theoretical specific energy, face practical challenges including polysulfide shuttling and low cell-level energy density. The surface-mediated polysulfide redox behavior results in a much higher exchange current in comparison with MgO and carbon. 2018.09.024.

Green Car Congress

OCTOBER 10, 2016

Researchers at South China Normal University in Guangzhou have developed a novel composite of sulfur loaded in micropore-rich carbon aerogel (CA-S) for use as a cathode in Li-sulfur batteries. These issues limit the practical application of lithium-sulfur battery. —Li et al. Click to enlarge.

Green Car Congress

NOVEMBER 27, 2021

Australia-based Li-S Energy has entered into an agreement with Janus Electric to develop and to test lithium sulfur and/or lithium-metal battery cells to suit the requirements of the Janus Electric exchangeable prime mover battery packs.

Green Car Congress

NOVEMBER 10, 2018

Researchers at Shanghai Jiao Tong University have developed a gel-like electrolyte induced by fumed alumina for dendrite-free Li deposition, lower over-potential and better cycle stability in lithium-sulfur batteries. An open-access paper on their work is published in the RSC journal Chemical Communications. —Lei et al.

Green Car Congress

SEPTEMBER 30, 2019

To develop higher capacity batteries, researchers have looked to lithium-sulfur batteries because of sulfur’s high theoretical capacity and energy density. It also consumes fresh lithium and electrolytes, and reduces battery performance. Credit: Xing Gao, Siwu Li, Ying Du and Bo Wang.

Green Car Congress

MAY 20, 2019

Researchers at Beihang University in Beijing have developed a linear molecule sulfur-rich organic material as sulfur cathode for a lithium-sulfur battery. The tetramethylthiuram disulfide-sulfur (TMTD-S) cathode material delivers an initial capacity of 685?mAh 1 at 0.2C (1?C?=?1061?mAh 1 after 200 cycles.

Green Car Congress

JANUARY 22, 2020

OXIS Energy has successfully tested its Lithium-sulfur (Li-S) battery cell prototypes at 471Wh/kg and is confident of achieving 500Wh/kg in the next 12 months. OXIS has also successfully developed a standard Li-S battery module that saves production time and cost.

Green Car Congress

MAY 10, 2018

Purdue engineers have used upcycled low-density polyethylene (LDPE) plastic to boost the lifespan of lithium-sulfur batteries. They first prepared porous sulfonated carbon (PSC) from LDPE plastic via microwave-promoted sulfonation. with cycle retention of 79% over 200 cycles.

Green Car Congress

DECEMBER 16, 2014

Vasant Kumar at the University of Cambridge and Professor Renjie Chen at the Beijing Institute of Technology has devised a three-dimensional hierarchical sandwich-type graphene sheet-sulfur/carbon (GS-S/C ZIF8-D ) composite to address performance-related issues in Lithium-sulfur batteries such as low efficiency and capacity degradation.

Green Car Congress

NOVEMBER 2, 2011

A team from Lawrence Berkeley National Laboratory and Tsinghua University (China) have synthesized graphene oxide-sulfur (GO-S) nanocomposite cathodes and applied them in lithium/sulfur cells to show a high reversible capacity of 950-1400 mAh g -1 and stable cycling for more than 50 deep cycles at 0.1C (1C = 1675 mA g -1 ).

Green Car Congress

MAY 16, 2014

Researchers at Tsinghua University have combined two types of carbon materials to create a new composite sulfur cathode material for a high-energy and high-power lithium-sulfur battery. Carbon atoms have six electrons: two are in 1s states, and four are valence electrons, occupying the 2s and 2p orbitals.

Green Car Congress

DECEMBER 17, 2018

Lithium-chalcogen batteries—e.g., lithium-sulfur (Li-S) and lithium selenium (Li-Se) systems— are promising candidates for high energy electrical storage solution. However, in order to achieve competitive energy density compared to current Li-ion batteries (i.e. > Scheme of SPC synthesis route.

Green Car Congress

APRIL 17, 2023

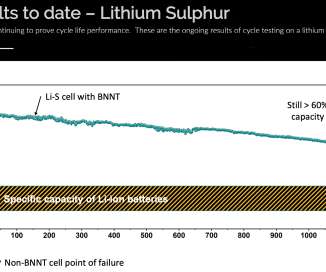

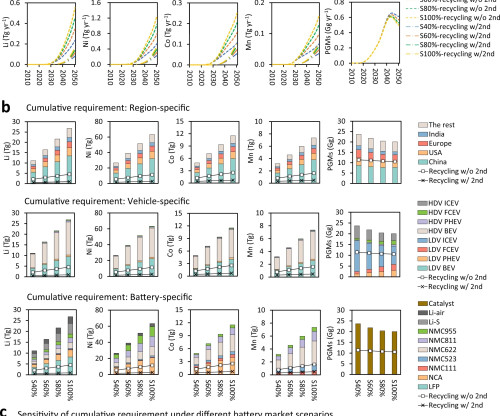

b) Region-specific/vehicle-specific/battery-specific cumulative (from 2010 to 2050) demand for critical metals and the cumulative potential secondary production from recycling. (c) c) Sensitivity of cumulative requirement under different battery scenarios. Recycling w/2nd” denotes retired batteries reused as ESSs before recycling.

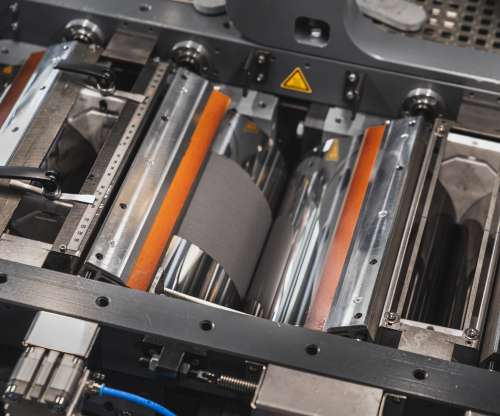

Green Car Congress

SEPTEMBER 5, 2021

Conventional processes for manufacturing battery electrodes involve mostly toxic solvents and require a lot of space and energy. DRYtraec thus is a promising solution developed by an interdisciplinary research team at Fraunhofer IWS in Dresden that focuses on the production of the battery electrodes.

Green Car Congress

OCTOBER 15, 2018

Researchers at Changchun University of Science and Technology in China have developed a nanobox strategy to improve the performance of lithium-sulfur batteries. Li–S batteries theoretically offer a specific energy density of 2600 Wh kg ?1 The system typically uses a lithium-metal anode and sulfur cathode.

Baua Electric

APRIL 12, 2024

Given India’s dependence on 100% imported lithium-ion cells for electric vehicle batteries, there exists a compelling drive to cultivate indigenous cell and battery manufacturing capacities to meet the burgeoning demands. Log9 has an impressive record of bringing world-leading battery technology to market.

Green Car Congress

SEPTEMBER 30, 2014

Fraunhofer IWS in Dresden, Germany will hold its 3rd annual workshop on Lithium-sulfur batteries from 12-13 November 2014. As with the prior Lithium-Sulfur Battery Workshops in 2012 and 2013, this year’s symposium will bring together an international audience of scientists and industrial customers.

Green Car Congress

AUGUST 26, 2014

The composite shows good rate performance and excellent cycling stability for use as a cathode material in Lithium-sulfur batteries. Another approach is to protect the anode to reduce the sulfur shuttle effect, and thereby extend cycling life.

Teslarati

SEPTEMBER 13, 2023

It appears that Tesla is considering Chinese battery components manufacturer Sunrise New Energy as a potential supplier, according to a new report. Sunrise New Energy said on Wednesday that Tesla has expressed interest in the manufacturer’s battery component products, as reported by Reuters. billion as soon as mid-2024.

Green Car Congress

SEPTEMBER 28, 2015

Researchers from Central South University in Changsha, China, have developed a separator with a nitrogen-doped porous hollow carbon sphere (NHC) coating for use in Li-S batteries. The NHC-decorated separator enormously improves the utilization of active material and enhances electrochemical performance. 2015.09.067.

Green Car Congress

MARCH 28, 2018

Researchers at The University of Texas at Dallas have used two-dimensional (2D) MoS 2 (molybdenum disulfide) as a protective layer for Li-metal anodes, greatly improving the performances of Li–S batteries. This approach, they suggested, could lead to the realization of high energy density and safe Li-metal-based batteries. Chae et al.

Expert insights. Personalized for you.

We have resent the email to

Are you sure you want to cancel your subscriptions?

Let's personalize your content