Lithium-ion battery recycler ABTC expands operations and capacity with newly purchased facility

Green Car Congress

MARCH 9, 2023

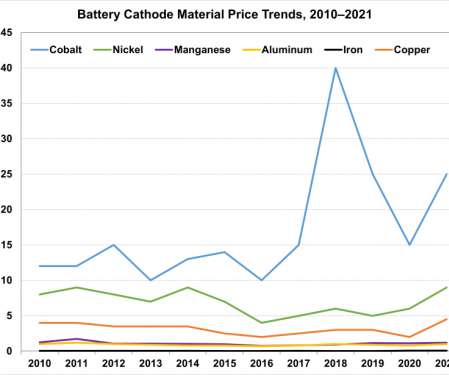

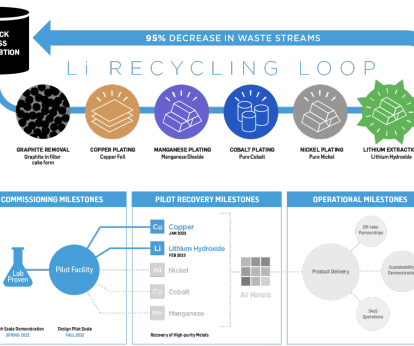

The demand for domestically produced and sustainably sourced battery metals has grown at a near insatiable rate over recent years, as the domestic manufacturing capacity of lithium-ion batteries has grown exponentially from less than 50 GWh/year to now more than 700 GWh/year of operational and announced capacity.

Let's personalize your content