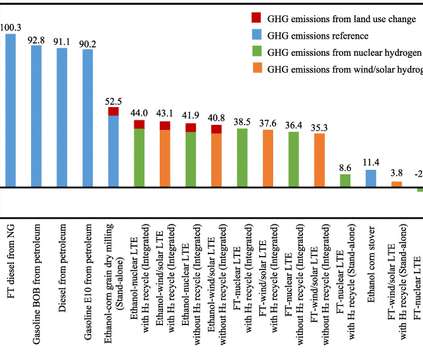

Argonne study shows range of GHG reductions for electrofuel Fischer-Tropsch; up to 108% reduction

Green Car Congress

MARCH 8, 2021

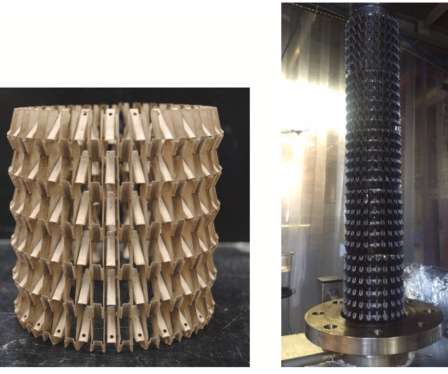

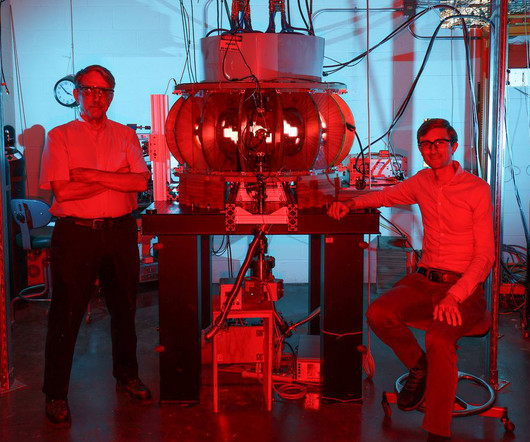

A team at Argonne National Laboratory’s Systems Assessment Center has evaluated the well-to-wheel (WTW) greenhouse gas (GHG) emissions of Fischer–Tropsch (FT) fuels produced via various electrolytic H 2 pathways and CO 2 sources; using various process designs (i.e.,

Let's personalize your content